Moderator Yang Xiwen

The iPhone8 may use rumors of a full glass body, which has greatly attracted the development of glass technology. Coupled with the rise of monitors and some optical industries in the past decade, "glass" has changed from a traditional industry to a corner of the high-tech industry, and has even become one of the countries' competitive fields.

In order to make Taiwan's glass products more competitive with the market and promote cooperation between the glass technology industry, with the support of the Ministry of Science and Technology, the "Advanced Special Glass Technology and Manufacturing Cooperation Alliance" brings together domestic upstream and downstream related businesses to provide member glass professional. Knowledge and glass process and testing technology professional services, counseling members to develop new products or new technologies, successfully coaching 30 member manufacturers, and implementing 13 industry-university cooperation projects with a total amount of about 6.4 million yuan.

Ten years to grind a sword. Final Glass Field maintain its

Professor Yang Xiwen, who originally studied film technology, went to Unite University in 1993 after graduation. He was involved in the field of glass materials research at that time. Professor Yang Xiwen said that this turning point is like "teaching Shaolin, changing to Wudang", but Because of the solid foundation and hard work, after establishing the first R&D center based on "glass and fiber materials" in the country, it has established professional research characteristics for the National Unite University Materials Department.

Patent certificate obtained by the alliance (partial)

With the trend of technology development, glass materials and technology have become one of the contemporary schools. Based on the solid foundation of glass materials and fiber materials education and research experience for more than 10 years, the "Special Glass Technology and Manufacturing Cooperation Alliance" has 26 patent technologies in the Republic of China and the United States, covering glass formulation design and melting, glass forming. Core technologies such as glass structure, bond analysis, and glass property testing, and master key technologies such as glass formulation, process, property analysis, and special structure analysis. It not only supports industry development technology in R&D and process, but also understands the needs of the industry in the process of cooperation with the industry, focuses on the focus of its own business, and implements the project in a "customer-oriented" way to meet customer needs.

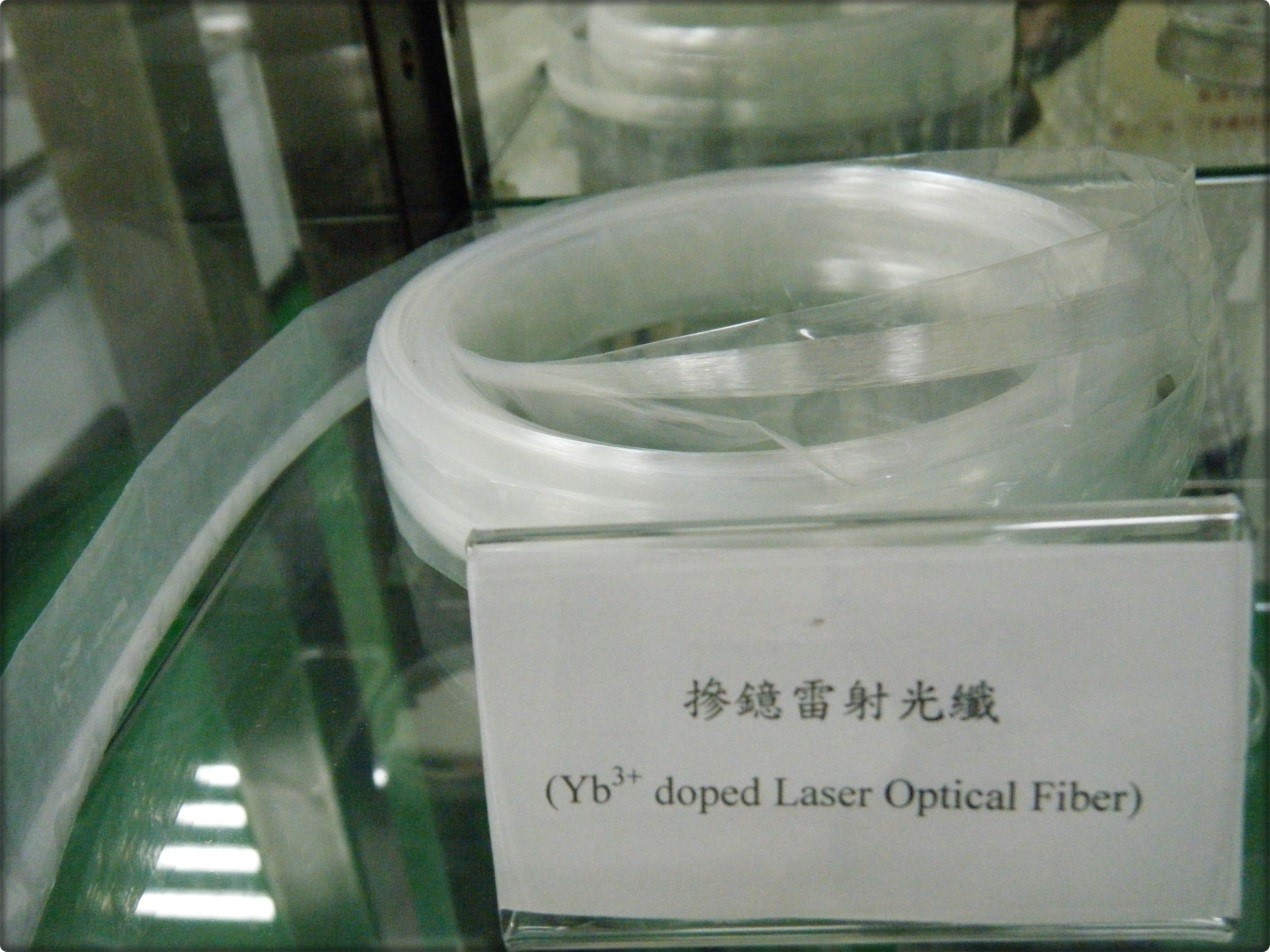

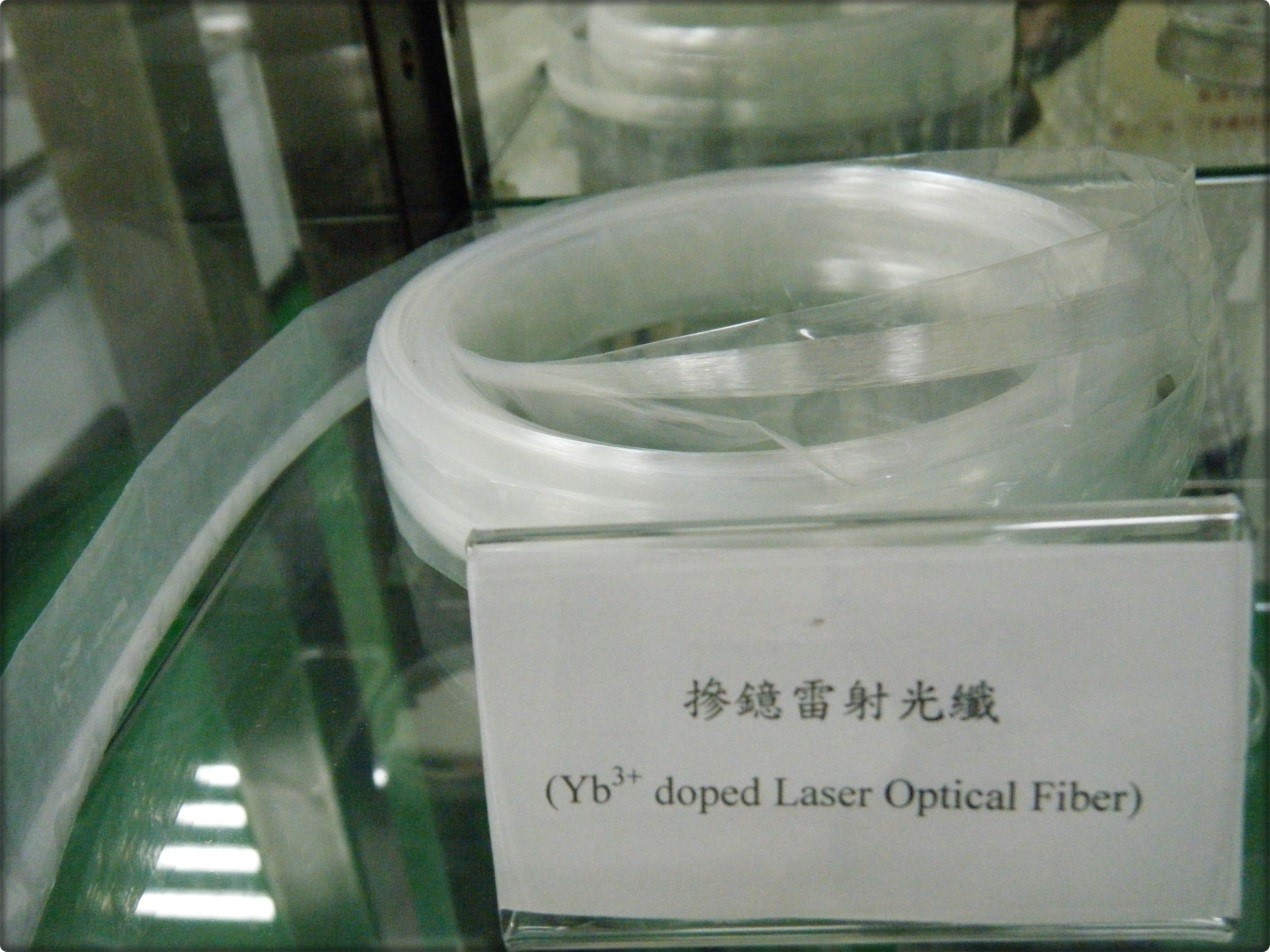

Laser fiber

The results of production and learning cooperation are bright Pulling international competitiveness

In order to strengthen the interaction and interaction with the industry, the focus of the research theme and planning of the alliance has also gradually changed from pure academic field to the development of glass material theory and industrial application technology and key materials. Professor Yang Xiwen pointed out that Taiwan's research and development of glass formulas is relatively weak, and the shortage of academic talents emphasizes the latter process. The alliance has R&D technology and molding technology. Therefore, the future plans will adopt a full-service customized service model to Technical needs and product research and development are prioritized, and courses such as talent training and product customization analysis design are widely promoted to assist the development of emerging application products in the industry, and the research and development energy of the academic community is injected into the industry, and it is expected to jointly develop the technological upgrades required by the industry. Shorten the gap between learning and use, enhance members' profitability and strengthen international competitiveness.

Taiwan Advanced Systems Corporation visited

The "Advanced Specialized Glass Technology and Manufacturing Cooperation Alliance" has so far coached 30 member manufacturers, including 8 technology transfer, totaling 2.07 million yuan; 13 industry-university cooperation plans, with a total amount of about 6.4 million yuan, the results are quite eye-catching . Among them, the most eye-catching is to assist Yamei Resin Glass Co., Ltd. to successfully develop new products for lamp-based coffee stoves, and go to France to participate in the "2014 and 2015 Paris International Invention Exhibition (ConcoursLepine)" to "multi-layer The coffee filter patent won the bronze and silver medals, and the coffee cup group marketing was promoted to the European market, so that the brewed coffee can no longer use the alcohol lamp or the gas stove to become the light of Taiwan.

In addition, Hengying's "Testing Radiation Dose Glass" is the world's largest synchrotron radiation center for the application of glass formulation results. Helmut Vincke, head of the Radiation Protection, European Organization for Nuclear Research Group) attaches great importance to and inquires, and actively requests the provision of commercially available high-radiation dosimeters or cooperative development feasibility.

Hengying Company revealed that 200 pieces of radiation dose test pieces requested by the Nuclear Research Center have been sent to the Synchrotron Radiation Center for experiment. After one year, 5,000 pieces of radiation dose test pieces were ordered again, and Hengying received 20,000 yuan. US dollar order income.

Professor Yang Xiwen said that the alliance has achieved fruitful cooperation in undertaking technical services for members and assisting in the development of new technologies. In the service plan of the counseling vendors, in addition to continuing the research and development results in response to the needs of manufacturers, the company has made efforts to improve the existing technologies. In addition, we will continue to develop new technologies that are more in line with the needs of the industry to enhance the technical capabilities of glass. This will not only train domestic glass professionals, but also enhance the energy of related equipment.

Expand Knowledge Exchange Chain talent Demand

Industry-industry-university-research exchanges, technology transfer, and talent training will all play a greater synergy due to resource integration and institutionalized focus." Professor Yang Xiwen believes that the improvement of manufacturers' technology must strengthen online employees. The expertise, as well as the continuous introduction of new blood, are achieved.

The Alliance held a number of glass technology seminars and recruitment briefings, including Xinxing Electronics, Taiwan Glass, Zhengda, Jinyu, Daxie, Xinghe, Yuhui, Hanyang Business Group, Yanneng Technology, Taiwan Advanced, Heng 61 companies including ying enterprise, China glaze, Donglian optical, Yuanxiao Glass, Atomic Energy Commission, Nuclear Energy Institute, Jiesheng Industrial, Industrial and Industrial Research Institute, and 219 domestic industry participants participated in the promotion of glass technology exchange and promotion. Industrial development of related products.

Alliance visits Daxie。

The Alliance also handles advanced glass and glass testing technology courses to assist members in professional talent education and training. Jiesheng, China Glaze, Taiwan Advanced, Hengying Enterprise, Taiwan Glass, Yuanxiao Glass, Zhongtian Engineering, Xinghe Optoelectronics, Germany Well-known companies such as Platinum Technology, Xinxing Electronics, Zhengda Optoelectronics, Jiebao, Donglian, Dayu, Platinum Technology, Chengyan Technology, and Industrial Technology Research Institute have responded and participated in 263 person-times.

The addition of new blood to the industry is also one of the ways for manufacturers to improve. In order to effectively integrate production and education, the Alliance also assists university students and fresh graduates in preparing for job hunting by organizing employment fairs, understanding employment trends, and introducing company information and Establishing corporate image and popularity, successfully matching the mechanical, chemical, optoelectronic, energy and materials departments of the seniors in the internship and the glass industry new workforce 24 people, giving birth to a new wave of industry force, let more core key technology creation Higher added value.

Accelerate the pace of research and development, and promote mutual benefit and common prosperity

The phased achievements of the "Advanced Specialized Glass Technology and Manufacturing Cooperation Alliance" have been seen in the outstanding performance of the industry, and their dedication to rooting and horizontal diffusion has also received support from the academic community. Professor Yang Xiwen hopes that the Alliance can continue to be a strong backing to support the development of the industry, providing member glass expertise, glass industry glass process and testing technology professional services, counseling members to develop new products or technologies and participate in glass technology international industry consultation and activities. Collecting the latest international glass technology development trends, promoting cooperation between glass technology industries, improving the sound development of the industrial system, accelerating the upgrading of the glass industry, and developing unique market competitiveness.

Fiber drawing tower.

Professor Yang Xiwen hopes that the alliance must strengthen the link between technology and application, effectively support the development needs of glass-related industries, and provide better services in the field of glass material property analysis technology, quality control technology, glass formulation and related process technology. The specific substantive feedback mechanism encourages the alliance research teachers and members to participate in industry-university cooperation and double the glass-related business.

In addition to continuing to provide more complete services, the company will continue to recruit potential members and diversify the glass industry cooperation network as soon as possible; continue to deepen the local enterprises, provide customized services and optimized technology, and enhance member profitability. Comprehensive resource integration, training domestic high-value-added advanced glass professional and technical manpower to achieve the goal of mutual prosperity between academic and industrial.