Contact us

Chen, Si-Ying

Tel: 037-382221

Fax:037-382222

Email :evaparis8411@nuu.edu.tw

glassfiber@nuu.edu.tw

Service hours

13:00 ~ 16:00

Glass Property Analysis Laboratory (2)

RadiofrequencySplash Plating Machine (RF sputter)

Coating applications are quite extensive, in many semiconductor processes, optical glass and so on areUsed to splash PlatingRide. RadiofrequencySplash Plating MachineIt is a thin film instrument which uses physical methods. Its internal operations are basically configured in一Vacuum cavity, withSplash-plated excitation gun generationPlasma. Coating principle is the production of high-energy plasma in the vacuum cavity, the use of plasma impact target material(Plated objects:Are metals, metal oxides, or inorganic non-metallic objects),The target materialThe atom hits the surface,To make the target materialAtomic adhesion is deposited on the substrate.In the target materialThe electrode is imported between the substrate, the target is the cathode and the substrate is the anode, while the ions in the plasma are positively charged(Generally makeUse argon to excite it to be positively charged), these positive ions move toward the cathode, hitting the surface, while the negatively charged atoms in the hit target atom move toward the Yang Jiki plate and finally deposited on the surface.

The film is made to control the flow of gas in the cavity, through other gases, and the heating temperature of the substrate to changeIts process factors。 UseSplash Plating methodFilms are made compared to other physical sedimentary films(such as steaming plating, etc...)Fast plating rate for precise control The parameters of the process, its component control is better, can choose theCoated materialsMore extensive. Compared with the general chemical deposition method,(CVD),Using Splash-platedThin film film thickness is more uniform and dense.

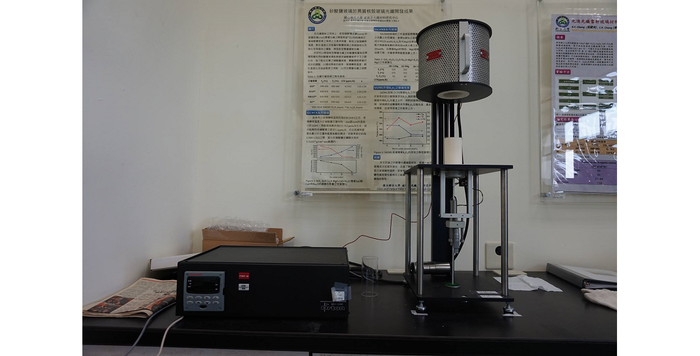

Glass softening viscosity tester

By loading a certain load weight in the middle of the glass rod and testing the resistance of the specimen to the added torque, the viscosity value of the specimen is shown by the precision load sensor. There is a close relationship between viscosity and temperature, and the higher the temperature, the lower the viscosity will be,This deviceThe viscosity at lower temperatures can be tested.

Waiting test Machine

Waiting test Machine is throughXenon ARC Lamps ASLight source, and adjust irradiation intensity rain to replace the filter water sleeve, and can control the temperature and humidity inside the test areaDegree of environmentalAnd rain action, simulating the damage to the material and aging conditions in different irradiation environments.