Contact us

Chen, Si-Ying

Tel: 037-382221

Fax:037-382222

Email :evaparis8411@nuu.edu.tw

glassfiber@nuu.edu.tw

Service hours

13:00 ~ 16:00

Optical Fiber Process Lab

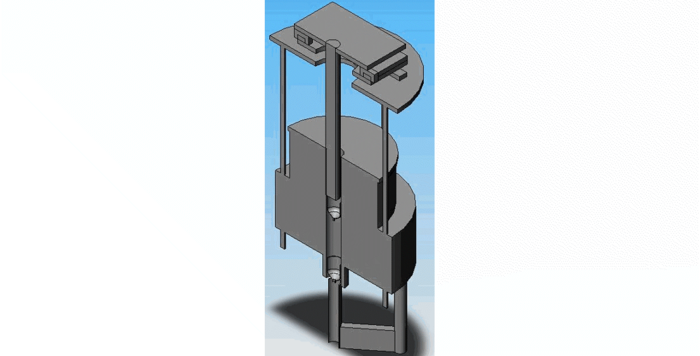

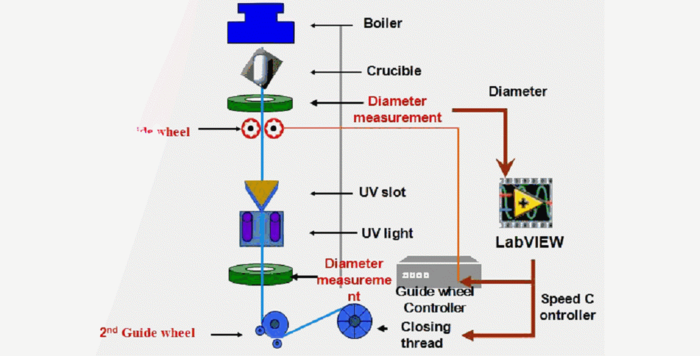

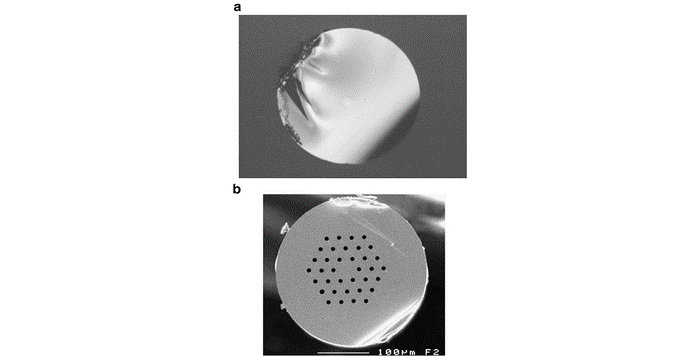

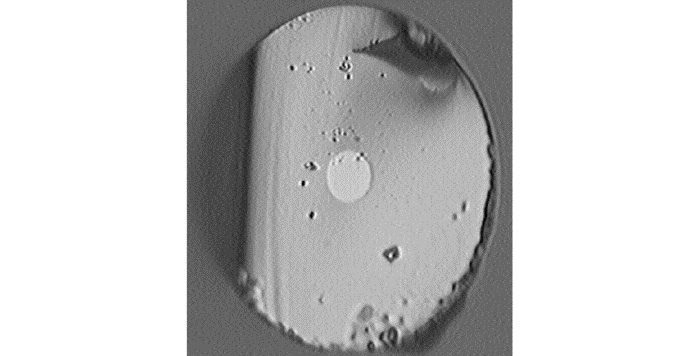

Generally, optical fiber preform production uses a MCVD (Improved Chemical Vapor Deposition) method to produce a light rod, which is a high-cost production technique. In order to reduce the cost, the experimental equipment can use the internal and external double-twisted fiber to change the composition of core and clad at any time, without using expensive production equipment and processes to reduce the cost, and later improved into a tube-shaped preform. Ways to improve fiber quality and develop a variety of special-spec fiber, such as single mode fiber, double-clad fiber, D-shaped fiber. In the measurement line diameter, the ray double-axis diameter is measured by the lightning ray diameter measurement control, and the optical fiber can be controlled within the conforming specifications. For example, the commercially available specification is 125 μm, and the wire diameter monitoring feedback device can automatically adjust the rotation speed and the wire diameter. The relationship between the two axes of the XY can also be used to adjust the roundness of the fiber.

Bar-like tube method and pre-made light bar method fiber comparison table:

|

|

Multiple layers |

Cost |

Asymmetric |

Variability |

Maturity |

|

Analogy crucible |

○ |

◎ |

○ |

◎ |

△ |

|

Preform |

○ |

△ |

※ |

△ |

○ |

|

◎Excellent; ○Good; △Bad; ※Unable |

|||||